TECHNOLOGY

Generation II

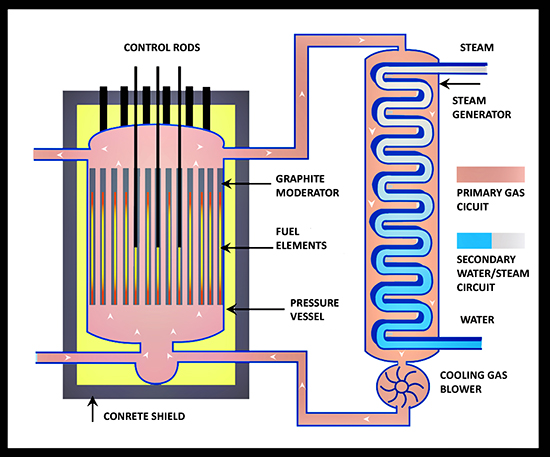

GCR ( Graphite Gas Reactor)

Source: "Power Reactors - Characteristics. 2008 WNA Pocket Guide", World Nuclear Association, July 2008 [26]

GCR (Gas Cooled Reactor) is graphite moderated and gas cooled reactor. There are two types of GCR. First, the Magnox (named from magnesium alloy fuel can) and second, AGR - Advanced Gas (cooled) Reactor. Both are cooled with carbon dioxide, but use different fuel. The AGR was developed from the Magnox. Using gas as a coolant allows for increase its temperature in core outlet without pressure raising. It is possible to work with high temperature and moderate pressure. It makes pressure vessel construction less expensive. The best cooling parameters has helium, but its price is very high, hence carbon dioxide is in used. Gas coolant needs very large exchange surface to ensure proper cooling. GCR power density is only 1 MW/m3. Therefore GCRs are not large assets, only up to 600 MW. A gas takes heat from the core and passes it, through heat exchanger, to water to produce a steam with parameters of 400ºC / 5 MPa. To achieve CO2 flow required in the core, high power compressors are needed. Therefore, there are 4-6 heat exchangers working with one reactor, and circuits are segmented. GCR has similar design to RMBK construction. It has vertical graphite blocks with fuel tubes. In GCR graphite is cooling by CO2, before gas moves to fuel. Graphite temperature is never higher than 400ºC. In the AGR reactors magnesium alloy fuel cans were replaced with stainless steel fuel cans and natural uranium was replaced with enriched UO2. It allowed for increase temperature in core outlet and as consequence steam parameters were improved up to 566ºC / 16 MPa. They are comparable to parameters obtained in fossil fuel power plants. Burn-up also increase from 4,7 MWd/kg to 18 MWd/kg. Like Candu reactors, GCRs can be refuelled during normal operation. The Magnox rectors net efficiency is around of 31,5 %. It uses fuel without enrichment as natural metal uranium. The AGR reactors net efficiency is higher and reach level of 41 %. This is the highest efficiency among operating reactors. AGRs use enriched fuel in uranium dioxide. An enrichment level is 2-3 % U-235. Both reactors GCR and AGR have become very popular especially in The Great Britain. They have not interested industry in other countries. Nowadays the GCR reactors are no longer produced. [16],[21],[24],[30]

-

Nuclear power industry|

Technology|

The electricity supply system aspect|

Economics|

Environment|

Public aspect|

Future|

Legislation|

References|