TECHNOLOGY

Generation IV

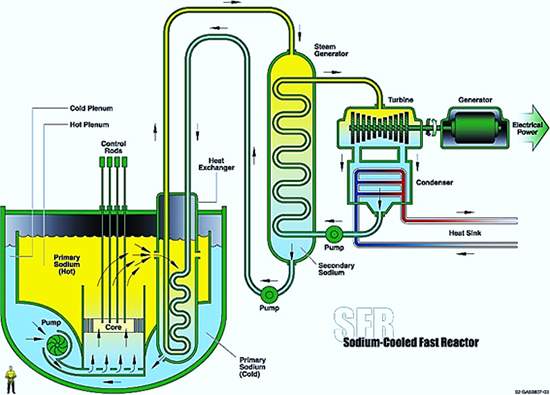

SFR ( Sodium Cooled Fast Reactor)

Source: "A technology Roadmap for Generation IV Nuclear Energy Systems", U.S. DOE Nuclear Energy Research Advisory Committee and Generation IV International Forum, 12.2002, http://www.gen-4.org/PDFs/GenIVRoadmap.pdf [55]

The SFR reactor is fast neutron reactor with liquid sodium cooling and closed fuel cycle. It allows to reach high power density with minimal coolant volume. This concept derives basic technology from fast neutrons reactors development and sodium reactors, been developing in the past. Description of fast breeder reactors, that were in commercial use in Russia and France can be found here . Therefore the SFR reactor is planned to be deployable as the first generation IV system. Moreover the SFR design is put on target by GIF, because of its possibility to nuclear wastes management (including actinides management) and fuel breeding. Nevertheless electricity generation is possible and even welcomed. Especially when, owning to innovations, brought by technology progress, capital cost will decrease. Moreover it is proven that sodium reactors are able to use almost all uranium in the fuel, when in thermal reactors uranium usage reaches only 1%. [54]. The SFR is triple loop construction as today FBR reactor are. The primary circuit can be arrange in a pool or a compact loop. Power capacity has not been decided yet. It is possible to design SFR as small modular construction or as large monolithic reactors with power capacity 1700 MWe. Fuel cycle type depends on power capacity. For smaller units it can be advanced aqueous recycling method with MOX fuel, for larger metallurgical processing recycling method with mixed metal alloy fuel is being considered. In third circuit for the heat conversion, to enhance efficiency as much as possible, carbon dioxide use instead of water is under consideration. The reactor outlet temperature is 530 - 550 ºC. The SFR includes specific safety systems complied with Generation IV guidelines. To reduce proliferation risk the SFR concept does not have blanket around the core, that FBR reactors were equipped with on purpose plutonium accumulation. The SFR commercial deployment is planned until 2020. [50],[51],[52],[54],[55], [56],[57],[58],[59]

-

Nuclear power industry|

Technology|

The electricity supply system aspect|

Economics|

Environment|

Public aspect|

Future|

Legislation|

References|