MOTOR-DRIVEN SYSTEMS

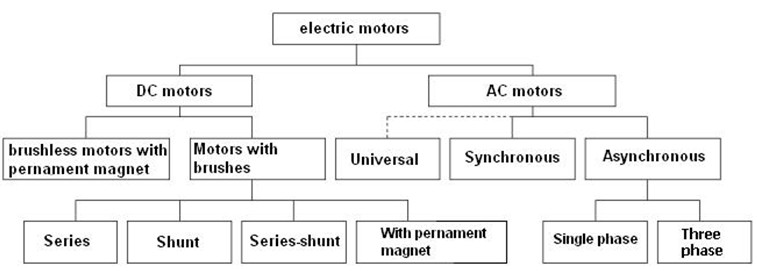

Electric motors are devices designed to convert electric power into mechanical energy. However many types of them can be used to produce electrical energy when propelled as well. The way of creating the torque by the motors is caused by Lorentz force principle. It states that every current carrying conductor placed in a magnetic field experiences a force known as Lorentz force. Electric motors are made from stators and rotors and depending on the construction they do different things. Figure 15 presents types of electric motors. Two main groups of the motors are DC and AC motors, although that classification is not very accurate because many of the DC motors can be run on AC power.

In the DC motors stators are made of magnets or electromagnets with field windings, their task is to produce electromagnetic field in the motors. Rotors are made of the shafts which pass the torque and square conductors which are connected to the grid. When the motor is powered by the DC two electromagnetic fields which are created in rotor and stator create a torque propelling the shaft. DC motors are known for its reliability and simple speed control. However their life span and maintenance costs are the disadvantages due to the components such as commutators and brushes which have to be often replaced.

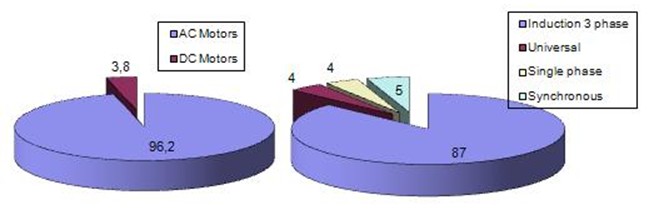

The other main type of electric motors are AC motors which are divided into synchronous and asynchronous motors. Those two types have stators constructed in the same way. They are built from ferromagnetic material and field windings making an electromagnet. In synchronous motors rotors are made of solid ferromagnetic material with windings wrapped on it. The windings on the rotor have to be powered with DC from an external power source. When both stator and rotor are powered, a synchronous magnetic field is created by the stator which is followed by the static magnetic field created by the rotor. Construction of asynchronous rotors is simpler. It is usually a squirrel-cage made of conductive bars shorted at both ends. When the stator is powered it creates a magnetic field spinning around the rotor. The field induces a current flow in the bars of the stator which then creates a magnetic field in the rotor. Those two fields create a torque spinning the shaft. There are many kinds of different synchronous and asynchronous motors, although the vast majority of all the motors used today are squirrel-cage asynchronous motors described above (Graph 5). It is caused by the fact that this kinds of motors are inexpensive, high efficient, manageable, less complicated, and they have longer life span in comparison to other motors. The biggest disadvantage of squirrel-cage motors was an impossibility of changing the rotation speed of the shaft which could be obtained by the adjustment of the powered frequency. However with the development of the power electronics that status has changed and now it is not a disadvantage at all. Further mentions about motors will be about squirrel-cage asynchronous motors only.

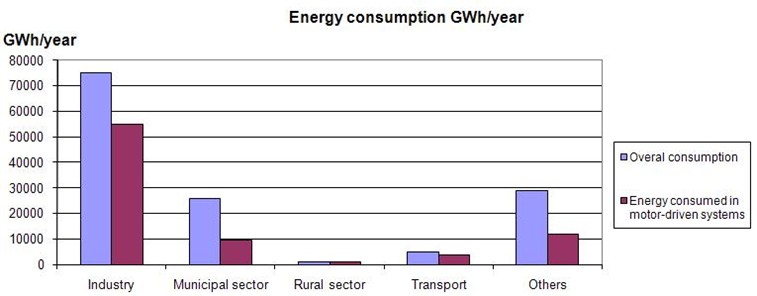

Electric motors are the most frequently used energy loader. Graph 6 presents years motors energy usage compared to the overall energy usage depending on the sectors in Poland in 2004-2008. As can be seen a contribution of energy used by motors is large. Even in the household sector where it might have seemed that motors are not very common, the energy used by them represents about 35% of overall energy usage. It is caused by the fact that motors are everywhere, they are in the pumps, fans, refrigerators, vacuum cleaners, air conditionings or cookers.

A large number of electric motors and plenty of energy used by them cause that the energy loss in the field of electric motors is significant.

-

Definition of energy conservation and demand side management|

Technologies|

Financial funds|

Legislative and normative issues|

Data base

Copyrights © Arkadiusz Mysiakowski