MOTOR-DRIVEN SYSTEMS

HIGH EFFICIENT ELECTRIC MOTORS

The efficiency of electric motors is different depending on the type of the motor. It is higher in high-power machines and lower in the low-power ones. It usually varies between 75% and 95%. Many constructors of electric motors have pursued to build more efficient and more reliable devices which are defined as high efficient electric motors.

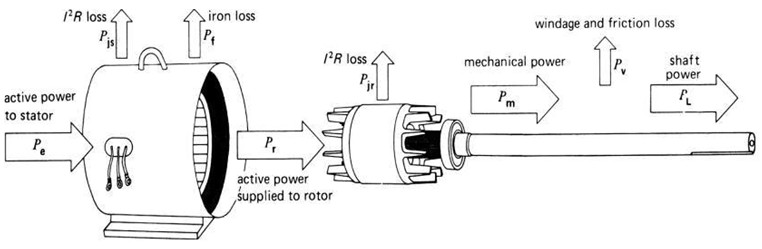

Figure 16 presents places in the motor when the energy is lost. To construct a high efficient electric motors all those losses have to be minimized. It requires a usage of new building techniques and materials of better quality. The losses in the field windings of the stator are resistance losses. The resistance losses are explained in chapter 3.1.2.1. To decrease them the windings should be larger in diameter. Also the length of winding overhang should be shortened.

Another place when losses occur is a stator itself when core losses appear. Stators are made of ferromagnetic material and its main task is to guide a magnetic field within an electric machine. Movement of a magnetic field in the stator induces currents around it which are not desirable. The currents are described as eddy currents and they induce their own fields which oppose the main magnetic field. To minimize eddy currents stators are made of electric steel. Electric steel consists mainly of iron (ferromagnetic material) and silicon (increases the resistivity) also it is in form of flat stripes. The high efficient electric motors have stators made of very thin and long electric steels. It requires very expensive and accurate technology to produce such a component.

Energy losses in motors are a source of heat which has to be constantly removed out of the machine to work properly. It can obtained by the motion of the rotor or in the majority of cases by a fan installed on the shaft. However the cooling system also produces extra losses referred to as ventilation losses. This is why it is desired to construct a stator with better aerodynamic performance. Also the installed fans and ventilators should be lesser and front of the shaft should be smoother.

The rotors would not be able to rotate if there were no bearings connecting them to the stators. However even though the bearings severely simplify the movement of the rotor they are still a source of losses caused by friction. This is why the high efficient motors require high quality bearings which have to be optimally true to the electric motor.

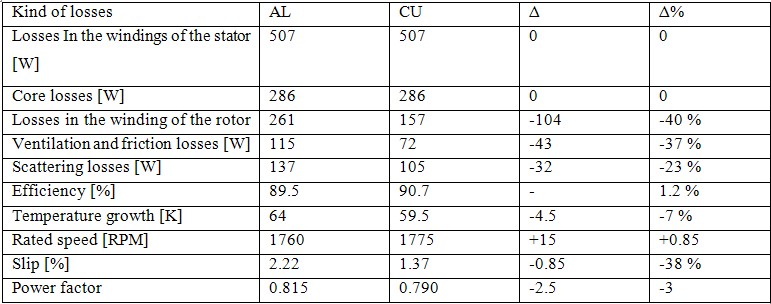

As in the case of stators the rotors have windings who induce resistance losses. In squirrel-cage motors the windings are in form of the bars constructed of the aluminum or copper. To reduce the losses and make the electric device more efficient it is essential to produce windings made of copper. Table 4 presents performances of the same squirrel-cage asynchronous 11kW motor with cage made of aluminum and copper. As can be seen a use of copper improved the overall efficiency by 1.2% which is a significant value.

All the efforts explained above require modern and expensive technologies. That makes that high efficient electric motors are expensive and not very common. However the capital costs of the motors compared to their maintenance costs are little. This including the promotion of electric motors by various organizations results in constant growth of popularity of high efficient electric motors. According to Polish Energy Efficiency Motors Programme (PEMP) a real option of reducing the energy consumption by using high efficiency electric motors estimates between 2 and 8% of less energy used.

-

Definition of energy conservation and demand side management|

Technologies|

Financial funds|

Legislative and normative issues|

Data base

Copyrights © Arkadiusz Mysiakowski